CLEAN ROOMS

Clean Rooms, also called white rooms, are controlled contamination environments according to the ISO 14644 standard, in which the atmosphere is controlled so that there is a very low content of powder micro -articles, and in which humidity and pressure temperature are regulated. If the absence of germs, bacteria and pathogens is added to the aforementioned requirements, the white room becomes a sterile room

Clean room components

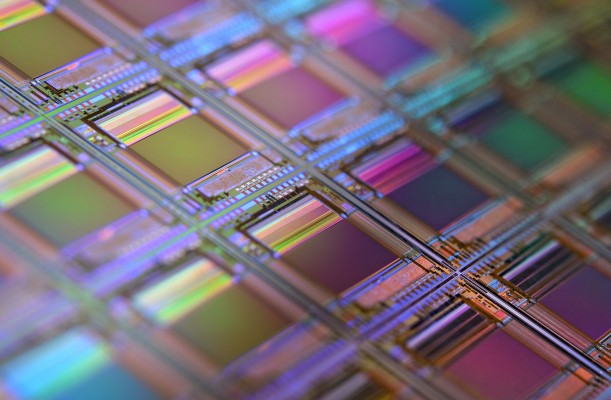

Before talking about the components that characterize a clean room, it is useful to know in which sectors these are used: hospital and medical, pharmaceutical, food, research, industrial (in particular microelectronics but not only). Knowing the application sectors is useful to understand why a clean room is always characterized by a laminar flow of air, or by a transverse flow of air.

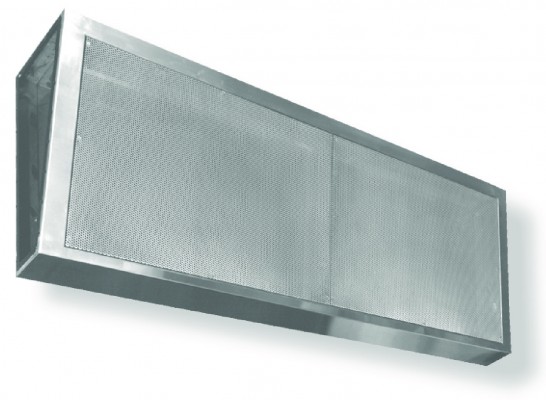

To realize the laminar flow (or transversal), filter diffusers for laminar flow are installed on the ceiling or on the wall (in the case of transverse flow) and suction grilles on the floor or on the wall opposite the diffuser.

The air is filtered over and over again, and even changed up to 600 times per hour, in order to make it of the degree of purity required by the reference ISO class. The ISO classes for clean rooms range from ISO 9 (the most "contaminated") up to ISO 1 (the cleanest).

Use of clean room components and filters

The absolute filters are installed in the filter holders housed in the diffusers and sealed with polyurethane mechanical seals, or with gel seals in the case of applications with more demanding specifications.

The modules and frames of the laminar flow filter diffusers can also contain inside the fans useful for moving the air, they can be integrated into the false ceiling or installed as a laminar flow hood, and typically have a remote control system to manage the different functions available.

Given the type of applications involved, all devices are made with materials (e.g. anodized aluminum) that are non-porous, easy to clean and sterilize, and resistant to the products used for these purposes